We, in cooperation with Enerclear Services (Canada), supply Internal pipeline cleaning and coating services for pipeline from 3"-60", up to 20km length (depends on the pipe size), please contact us for more details.

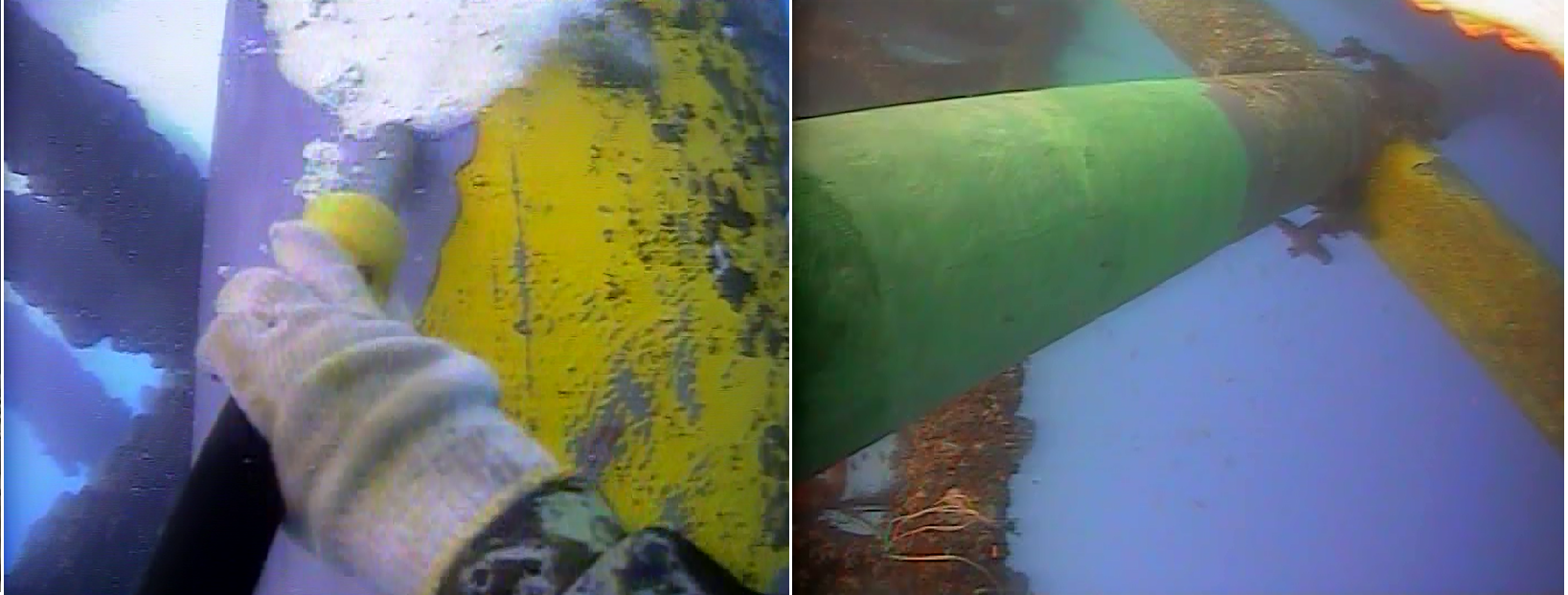

Pipeline Before Cleaning After cleaning After coating

Advantages:

- Minimally invasive in-situ procedure has reduced environmental impact (less dig-ups)

Benefits:

- Combats Scaling, Corrosion, Debris, Wax and Paraffin Deposition, and Reduces Process of Erosion

- Extends service life

- Reduce friction, increase flow efficiencies

- Cost savings as a result of addressing:

• Maintains pipe ID and throughput, minimized energy expenditure

• Downtime and related services/cost when leak occurs

• High pigging costs

• High chemical treatment cost

• Minimal impact on existing infrastructures and operations